Differentiation Between Cooling Towers

Differentiation Between Cooling Towers

Cooling towers come in different types, each planned for particular applications and working standards. Here’s a differentiation between a few common types of cooling towers:

Natural Draft Cooling Towers vs. Mechanical Draft Cooling Towers:

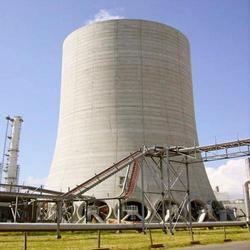

Natural Draft Cooling Towers:

– Work based on the guideline of buoyancy and the common stream of discuss.

– Taller in stature to induce a natural upward draft.

– Regularly utilized in expansive control plants and mechanical offices with high warm loads.

Mechanical Draft Cooling Towers:

– Utilize mechanical fans to draw discuss through the tower and upgrade heat exchange.

– Can be encourage categorized into initiated draft (fan at the best) or constrained draft (fan at the foot) cooling towers.

– Commonly utilized in commercial HVAC frameworks and medium to expansive mechanical forms.

Crossflow Cooling Towers vs. Counterflow Cooling Towers:

Crossflow Cooling Towers:

– Air streams horizontally across the falling water.

– Water is disseminated over the fill range, and discuss is drawn through the stream by fans.

– By and large more compact and cost-effective for littler applications.

Counterflow Cooling Towers:

– Air flows vertically upward against the falling water.

– Water is showered from the best, and discuss is drawn up through the tower by fans.

– For the most part more proficient for bigger mechanical applications.

Open Circuit Cooling Towers vs. Closed Circuit Cooling Towers:

Open Circuit (Evaporative) Cooling Towers:

– Permit direct contact between the method liquid (more often than not water) and the climate.

– Warm is exchanged through the vanishing of a parcel of the method water.

– Commonly utilized in applications where water quality isn’t a basic figure.

Closed Circuit (Dry or Crossover) Cooling Towers:

– Utilize a coil or plate warm exchanger to isolated the method liquid from the discuss.

– Warm is exchanged by implication, and there’s no coordinate contact between the method liquid and the environment.

– Favored in applications where water quality is vital, and the chance of defilement should be minimized.

Forced Draft Cooling Towers vs. Induced Draft Cooling Towers:

Forced Draft Cooling Towers:

– Fans are found at the foot of the tower, constraining discuss upwards through the fill.

– Easier access for maintenance.

– Commonly utilized in littler mechanical applications and HVAC frameworks.

Induced Draft Cooling Towers:

– Fans are found at the beat of the tower, actuating discuss to stream upward through the fill.

– Airflow is less likely to be influenced by wind.

– Commonly utilized in bigger mechanical applications and control plants.

Wooden Cooling Towers vs. Fiberglass/FRP Cooling Towers:

Wooden Cooling Towers:

– Traditionally constructed with wood for the structure.

– Effective in certain applications but may require more support.

Fiberglass/FRP Cooling Towers:

– Built with fiberglass-reinforced plastic for basic components.

– Safe to erosion, tough, and frequently require less support.

And ultimately, here you gained knowledge of the common sorts and differentiation between cooling towers. Understanding the particular characteristics and preferences of each type of cooling tower makes a difference in selecting the foremost appropriate framework for a specific application based on variables such as estimate, cooling necessities, water quality contemplations, and support inclinations.

Cooling Tower Solution for Customized Problems - Cool Fab Equipments January 11, 2024 at 9:23 pm

[…] a customized solution for cooling tower-related issues includes a exhaustive assessment of the particular problems faced and the unique […]

Optimizing Water and Energy Use in Evaporative Cooling Towers - Cool Fab Equipments March 21, 2024 at 12:46 pm

[…] water and energy utilize in evaporative cooling towers is basic for improving effectiveness, reducing operating costs, and minimizing environmental […]