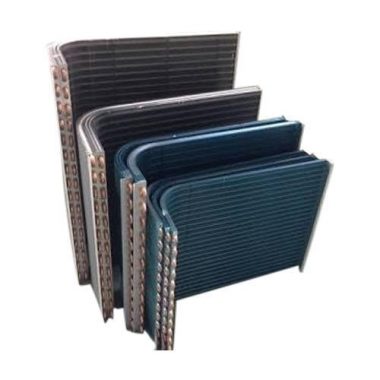

LOW-TEMPERATURE CONDENSER UNIT

The Low-Temperature Air Cooled Condensing Units we offered for the application in cold room temperatures from -35°c to -10°c come with a cooling capacity range of 1.2KW to 4.5KW. These condenser units can be supported by different refrigerant variants like R22, R134a, R404a and others.

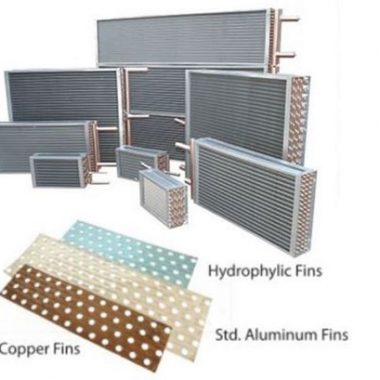

FIN TUBE EVAPORATOR COIL

Fin Tube Evaporator is a Heat exchanger, Heat is transferred from a substance to be cooled to the liquid refrigerant, the refrigerant absorbs heat and changes to vapour

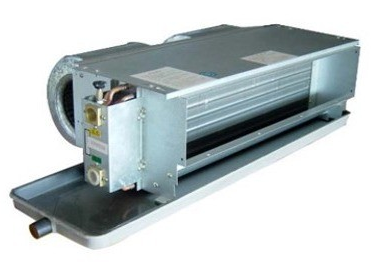

INDOOR COIL UNITS

Fan Coil Units are a fairly simple design. You can see where it gets it’s name from because it basically just a fan and a coil heat exchanger. The fans then force the air through the heating and/or cooling coils. They are just coil heat exchangers which simply heat the air up or cool it down, depending on the requirements for the local environment. Some units will be heating only, some will be cooling only and others will have both heating and cooling capabilities.