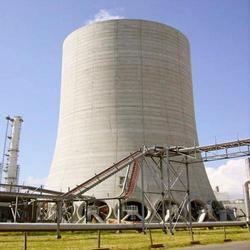

Forced Draft Cooling Towers

A forced draft cooling tower is a form of cooling tower. It forces air through the cooling tower using mechanical devices like fans or blowers. Pumping hot water from an industrial process into the tower, where it is dispersed across a fill material. These are act as a heat exchange medium and increases the exposed surface area to the air. The air is then forced through the tower by the fans or blowers. It causing the water to evaporate and expel heat into the atmosphere, so cooling the water.

Features Of Forced Draft Cooling Tower

Natural draught cooling towers, which rely on hot air rising naturally to draw air through the tower. These are often less efficient than forced draught cooling towers. They are more suited for usage in high-temperature situations and can manage a bigger volume of water. However, they could cost more to install and maintain and use more energy to run the fans or blowers.

Applications Of Forced Draft Cooling Tower

- Power generation: Forced draft cooling towers are commonly used in power plants to cool the water that is circulated through the power generation system. This helps to maintain the efficiency of the power generation process by keeping the temperature of the water within a desired range.

- Chemical processing: Forced draft cooling towers are also used in chemical processing plants to cool the water that is used in various chemical processes. This helps to prevent overheating and maintain process efficiency.

- Manufacturing: Forced draft cooling towers are used in a variety of manufacturing processes, including food processing, pulp and paper production, and plastics manufacturing. They help to cool the water that is used in these processes and maintain the efficiency of the manufacturing operation.

Cooling Tower Working Principles - Cool Fab Equipments December 29, 2023 at 11:45 pm

[…] or centrifugal fans: The purpose of the fan on top of the water-cooling tower is to bring in air from the bottom of the tower and move it up and out in the opposite direction of […]

Difference between a ‘Force Draft’ and ‘Induced Draft’ cooling tower ? - Cool Fab Equipments May 16, 2024 at 11:24 pm

[…] between a ‘Force Draft’ and ‘Induced Draft’ cooling tower? : The most difference between force draft and actuated […]