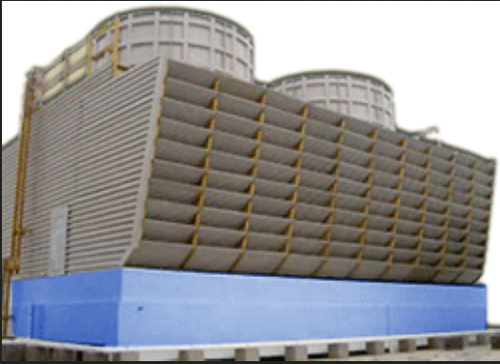

Crossflow Cooling Tower Components

Crossflow Cooling Tower Components

We has Cooling Tower Components and spares like motors, fan, spray nozzles, pressurized pipes, fills, drift eliminators and etc.,

Pressurized piping

Process water enters the counterflow cooling tower via a header that collects pressurised water at the nozzles, which break up the water flow into droplets.

Spray nozzles

Water is sprayed down onto the fills when it reaches the spray nozzles.

Fill

Panels onto which the water is sprayed and cascaded to expand its surface area and be in contact with the cooling air sucked into the tower through the fill.

Cold water basin

The container used to collect water that has been cooled down using fill media and placed at the base of the tower.

Fan

The fan, which is positioned at the top of the crossflow cooling tower to create airflow across the fills, is a device.

Drift Eliminators

panels constructed from materials like fills to stop water droplets entrained in the air stream from leaving the tower and preventing process water loss. The counterflow cooling tower design places them below the fan and above the nozzles.

Float

A float device controls the process water level that is lost to drift.

Makeup water inlet

This is where the water that is injected into the basin to maintain the correct process water levels.

Water outlet

The process water’s port of escape after cooling.

Overflow

A technique for letting surplus water levels in the basin out.

Drain

A part used to regulate how much mineral content builds up in the basin throughout the course of operation cycles.

These are the Crossflow Cooling Tower Components.