The Maintenance of Cooling Towers

The Maintenance of Cooling Towers

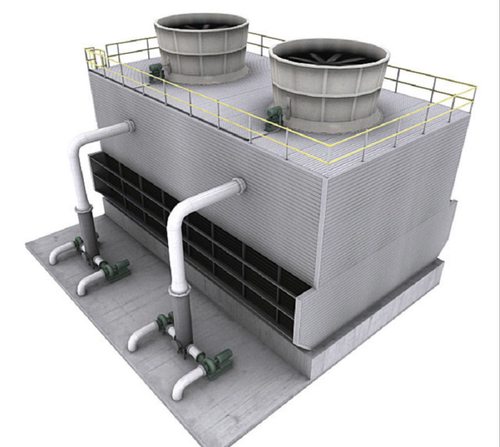

Cooling towers play a pivotal part in disseminating heat from industrial forms and HVAC systems. Legitimate support is basic to guarantee their effective and solid operation. Here’s a comprehensive direct on the maintenance of cooling towers:

1. Regular Inspection and Monitoring:

Conduct schedule visual assessments to recognize potential issues such as spills, erosion, or scaling. Execute a comprehensive observing system to track key parameters like water temperature, stream rates, and pressure.

2. Cleaning of Heat Exchange Surfaces:

Fouling, scaling, and natural development can hinder heat transfer effectiveness. Frequently clean the heat exchange surfaces, counting the fill material and tubes, to expel stores and maintain ideal thermal execution.

3. Water Treatment Programs:

Actualize a robust water treatment program to avoid scale arrangement, erosion, and microbial development. Frequently test water quality and alter chemical treatment in like manner to guarantee the life span of cooling tower components.

4. Lubrication of Moving Parts:

Heading, fans, and other moving parts should be lubricated routinely to decrease contact, minimize wear, and guarantee smooth operation. Take after manufacturer suggestions for the type and recurrence of grease.

5. Inspecting and Calibrating Controls:

Check and calibrate control devices, sensors, and valves to guarantee they are working inside indicated parameters. This incorporates checking the precision of temperature, pressure, and stream sensors.

6. Reviewing Drift Eliminators:

Frequently review and clean drift eliminators to preserve proficient water control and minimize water misfortune.

7. Review of Basin and Sump:

The basin and sump are basic components that collect and disperse water. Frequently review them for debris, silt, and signs of corrosion. Clean and evacuate any collected material to anticipate blockages.

8. Checking Belts and Pulleys:

In case the cooling tower has belt-driven components, routinely assess belts and pulleys for wear, pressure, and arrangement. Replace worn-out belts instantly to avoid execution issues and potential damage.

9. Reviewing and Testing Fans:

Fans are indispensably to the cooling handle. Frequently assess fan edges, center points, and engine mounts for signs of wear or damage.

10. Water Level Administration:

Maintain proper water levels within the cooling tower basin. Inadequately water levels can affect execution, whereas intemperate levels can lead to expanded water carryover. Introduce and maintain working overflow and makeup systems.

11. Winterization (Seasonal Maintenance):

For cooling towers uncovered to winter conditions, actualize winterization methods. This may incorporate depleting water, ensuring uncovered components from solidifying, and guaranteeing appropriate insulation.

12. Training and Documentation:

Guarantee that support work force are adequately prepared in cooling tower upkeep methods. Maintain detailed documentation of maintenance exercises, counting inspection reports, repairs, and water treatment records.

13. Emergency Preparedness:

Create and communicate crisis strategies for unexpected occasions such as spills, engine failures, or extreme weather conditions.

14. Upgrading and Modernization:

Consider intermittent updates or modernization projects to enhance the productivity and execution of cooling towers. This may incorporate retrofitting energy-efficient components, updating controls, or actualizing smart observing systems.

By following to a comprehensive maintenance plan, businesses can guarantee the life span, reliability, and ideal execution of cooling towers. Regular reviews, proactive cleaning, and adherence to water treatment conventions are fundamental components of an successful cooling tower maintenance methodology.

Descaling Cooling Systems - Cool Fab Equipments February 23, 2024 at 1:42 pm

[…] is a basic maintenance prepare for cooling systems, particularly those inclined to scale buildup due to difficult water or mineral-rich makeup water. […]