Shell and Tube Heat Exchangers

Shell and Tube Heat Exchangers

- Fixed Tube Sheet Heat Exchanger. In this type of exchanger, the tube sheet is welded to the shell. This leads to a…

- U- Tube Heat Exchanger. In a U-Tube exchanger, any type of front header may be used, and the rear header is typically…

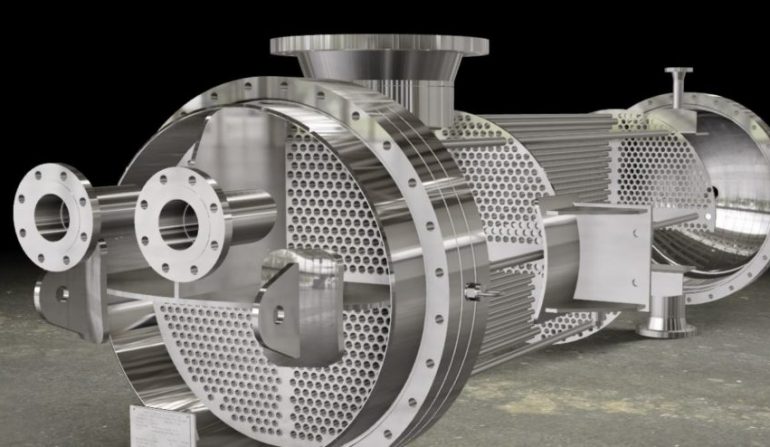

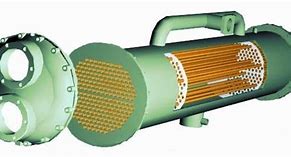

- Floating Head Heat Exchanger. In the floating head exchanger, the tube sheet is not welded to the shell at the rear. One of the most popular heat exchanger types is shell and tube heat exchangers, which are used in a wide range of pressure and temperature due to their capacity. Simply put, a shell and tube heat exchanger is a device that uses tubes inside an outer cylindrical shell to create a thermal contact between two working fluids. These two integral paths are usually made of thermally conductive metals (steel, aluminum alloys, etc.) that allow easy heat transfer.

- One of the working fluids passes from the inlet of the tubes to their outlet on the tube side, while on the shell side, a separate fluid passes over the tubes. The number of tubes in a tube bundle determines how much surface area is provided to the shell-side flow and thus how much heat is transferred. These devices are among the most effective heat exchange tools because they perform excellent heat transfer and are compact and easy to build and maintain. They are widely used in industries such as condensers, evaporators, turbine coolers, feedwater preheating, etc. The partition plate separates the lower and upper halves of the heat exchanger. The partition diverts the flowing medium through the tubes. Inlet / Discharge Inlet or discharge of the fluid medium that flows through the tubes or shell of the heat exchanger. Housing/Shell The housing/shell is used to contain the flowing medium

Shell and Tube Heat Exchangers

A shell & tube heat exchanger (STHE) is divided into three parts: The front end Shell Rear end Exchanger types based on the service Process fluid which is to be either heated up or cooled …he shell contains a tube bundle; one of the working fluids flows in the shell over the tubes. This set consists of the tubes, tube sheets, baffles, and tie rods to retain the bundle together.