Screw Chiller

Screw Chiller

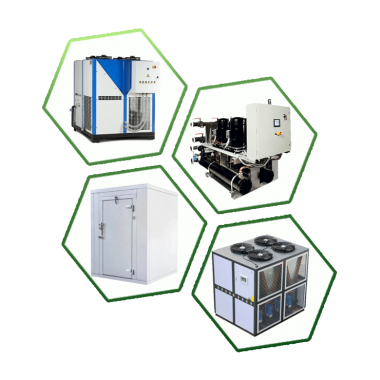

Screw Chiller is equipped with a corrosion-resistant heat exchanger, highly efficient condenser, and wide louver fin for enhanced heat transfer. Air-cooled Screw Chiller Features Line Up Inquiry To Buy High Efficiency Load Evaporator tube, By applying gravity type refrigerant distribution system, reliable operation is provided, and evaporation efficiency is improved by optimizing arrangement of eliminator and evaporator tube

-

Our air-cooled screw chillers can reduce your total cost of ownership because they are engineering for lower life cycle costs and reliability through design simplicity. Our compressor technology is direct drive, low speed (3600 rpm) with only two rotating parts for high reliability and efficiency.

-

The Air-cooled Screw Chillers, Chillers are suitable for working in extreme tropical weather conditions while maintaining energy and operational efficiency. The equipment is designed and manufactured in compliance with superior designing and manufacturing standards.

-

Air cooled Screw Chiller

Reduced Weight & Size

Valuable floor space can be saved by reducing installation area and weight.

-

Noise Reduction

It minimized turbulence in intake port and reduced inconvenience of noise by preventing outflow.

Black Box Feature

It stores and analyzes operation record for quick diagnosis to provide solution in case of failure.

-

High Efficiency Ice Thermal Storage System Applied

Ice Thermal Storage System cools the indoor area during the day and produces ice throughout the night. This applied solution allows more efficient product installation and energy consumption.

Optimized Central ControlControl solutions such as ACP and AC Smart enable easy monitoring and allow remote control to manage various HVAC models at anywhere

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream (such as air or process water). As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function.

-