Chiller Maintenance Best Practices

Chiller Maintenance Best Practices

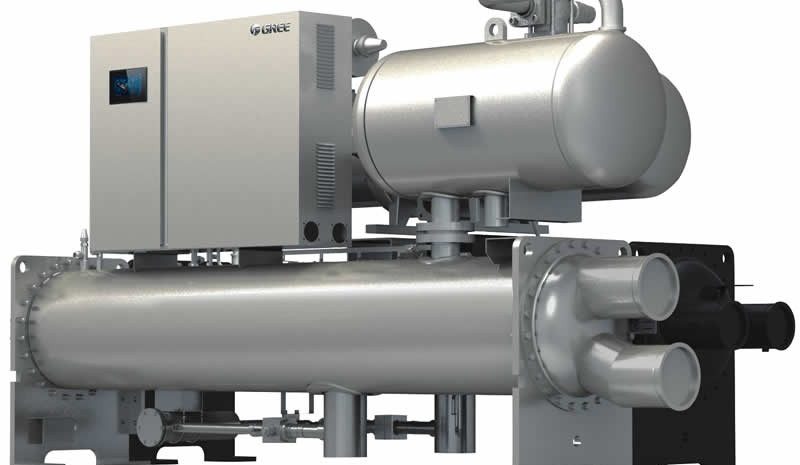

Chiller support is fundamental for guaranteeing ideal execution, energy productivity, and the life span of the system. Legitimate support practices offer assistance to avoid downtime, costly repairs, and untimely gear failure. Here are a few chiller maintenance best practices :

1) Regular inspection and monitoring:

- Conduct scheduled inspections of the chiller system, counting components such as compressors, condensers, evaporators, pumps, and controls. Screen working parameters such as temperatures, weights, and liquid levels to recognize any abnormalities or signs of potential issues.

2) Cleaning and Servicing Condenser and Evaporator Coils:

- Clean condenser and evaporator coils routinely to evacuate earth, debris, and scale buildup. Grimy coils impair heat exchange productivity, decrease cooling capacity, and increase energy utilization. Utilize suitable cleaning strategies and arrangements to anticipate damage to coil surfaces.

3) Checking refrigerant levels and purity:

- Occasionally check refrigerant levels and immaculateness to guarantee appropriate system operation. Low refrigerant levels can cause spills or other issues that have to be addressed promptly. Maintain refrigerant purity at manufacturer-recommended levels to anticipate compressor damage and maintain system effectiveness.

4) Inspecting and tightening electrical connections:

- Review electrical associations, terminals, and wiring for signs of corrosion, overheating, or free associations. Tighten loose associations and replace damaged or worn components to avoid electrical issues and guarantee the secure operation of the chiller system.

5) Lubricating Moving Parts:

- Lubricate headings, engines, fans, and other moving parts concur with producer proposals. Proper grease decreases grinding, minimizes wear and tear, and expands the life expectancy of mechanical components. Utilize consistent oils and take the suggested interims for lubrication maintenance.

6) Calibrating Controls and Sensors:

- Calibrate temperature, weight, and flow sensors frequently to guarantee precise estimation and control of system parameters. Appropriately calibrated controls offer assistance in maintaining optimal chiller execution, anticipating system glitches, and moving forward in energy productivity.

7) Inspecting and Cleaning Water Treatment Systems:

- If the chiller is water-cooled, inspect and clean water treatment systems, channels, strainers, and chemical dosing hardware frequently to avoid scale, erosion, and microbial development. Appropriate water treatment makes a difference in maintaining heat transfer effectiveness, avoiding fouling, and extending hardware life.

8) Testing Safety and Control Systems:

- Test security gadgets, cautions, and control systems to guarantee they work accurately and react suitably to abnormal working conditions. Confirm the appropriate operation of security shutdowns, pressure help valves, and emergency cooling systems to secure faculty and hardware.

9) Training and Documentation:

- Prepare maintenance personnel on appropriate chiller operation, upkeep strategies, and security conventions. Maintain point-by-point records of maintenance exercises, gear inspections, repairs, and execution data to track support history and recognize patterns over time.

By implementing these best practices for chiller maintenance, office supervisors can guarantee dependable operation, maximize energy proficiency, and prolong the life expectancy of their chiller systems. Standard support makes a difference in recognizing and addressing issues early, preventing costly downtime and repairs, and optimizing general system execution.