BUNDLED HEAT EXCHANGER

BUNDLED HEAT EXCHANGER

BUNDLED HEAT EXCHANGER

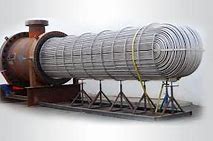

An intermediate tube bottom, having insert tubes arranged concentrically in the tubes, is located in the inlet chamber, with these insert tubes projecting out on both sides from the tubes and forming annular spaces therewith. The Bundled Heat Exchanger has an inlet tube bottom and an outlet tube bottom, in which are fastened the ends of tubes which connect the bottoms and through which the medium of high inlet temperature flows.

A Bundled Heat Exchanger for cooling a medium having a high inlet temperature. Toward the inlet chamber, the annular spaces open into an intermediate chamber limited by the inlet tube bottom and the intermediate tube bottom; in the opposite direction, the annular spaces open into a deflecting or reversing chamber sealingly covering the insert tubes.

Inter – Fitment is a major & critical point to be taken care off during the manufacture of the same, as the Tube Bundle is to be manufactured considering the tolerance of the existing heat Exchangers & not Code Tolerance.

For the same we either 1) Manufacture the Tube Bundle on manufacturer provided As Built Drawing or 2) Depute out Representative to the site for taking the actual dimension of the existing Tube Bundle and the Shell within which the same is fitting. Inter-Fitment guarantee is given by us.

TUBE BUNDLED HEAT EXCHANGER DESIGN AND FUNCTION

- The heat exchangers consist basically of housing and tube bundle.

- The housing is a welded construction and includes all connecting, joining and fastening elements.

- The standard smooth tube bundle to be installed is a two-way model.

- The exchanger design variation with U-tubes (U-design), the variation with the floating tube base (D-design) or with a fix compensator (K-design) all of them allow for large changes in length between the casing and the tube bundle due to heat expansion.

We also undertake the complete manufacture of U Tube Bundles. For the same we have complete Set of Fixtures for the 3/2″ & 1″ OD Tubes. The minimum Bending Radius carried out by us so far is 1.5D. U Tubes manufactured by us meet the TEMA Acceptance Norms of 16 % thinning & 10 % Ovality.

Application Bundled Heat Exchanger

- Power station technics

- Machine industry

- Gear manufacturing

- Chemical Industry

- Process engineering