Brazed Plate Heat Exchanger Working Principle

Brazed Plate Heat Exchanger Working Principle

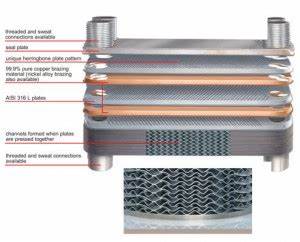

The Brazed Plate Heat Exchanger Working Principle is to transfer heat between two fluids using a series of corrugated metal plates that are brazed together. Brazed plate heat exchangers( BPHEs) are compact and effective heat transfer devices used in a variety of applications. Here is a breakdown of the main steps of the operation

Plate structure

- BPHE consists of several thin corrugated metal plates piled one on top of the other. The plates are generally made of stainless steel or other materials with good thermal conductivity.

Soldering process

- The plates are soldered together at the edges to form a solid unit. During brazing, the filler material melts and flows into the joint between the panels, forming a strong, endless joint.

Fluid inflow path

- The corrugations of the plates produce inflow paths for the two liquids involved in the heat exchange process. The plates are piled so that interspersing channels are created for each liquid.

Liquid entry point

- Two fluids, frequently appertained to as hot and cold fluids, enter a heat exchanger through specific entry points. Fluid flows through separate channels formed by the gaps between the plates.

Counter-Flow Arrangement

- In numerous brazed plate heat exchangers, hot and cold fluids flow in countercurrent flow. This means that they move in contrary directions, adding the effectiveness of heat transfer.

Heat transfer process

- As the liquid flows along its separate channel, heat is transferred from hot to cold liquid and vice versa through the thin metal plates. The corrugated design of the plates creates turbulence and promotes effective heat exchange.

Turbulence and mixing

- The turbulence created by the waves prevents the formation of boundary layers, improves liquid mixing, and ensures maximum heat transfer.

Compact design

- BPHE is known for its compact design, furnishing a large surface area for heat exchange in a fairly small space.

Efficiency

- The effectiveness of brazed plate heat exchangers is high due to the close thermal contact between the fluids and the large surface area available for heat transfer.

Application

- Brazed plate heat exchangers have applications in a variety of industries, including HVAC systems, refrigeration, artificial processes, and renewable energy systems.

Maintenance

- Maintenance of brazed plate heat exchangers is generally simple. frequently gutted by flushing the system, the compact design allows for easy replacement if demanded.

In summary, The Brazed Plate Heat Exchanger Working Principle involves heat transfer between two fluids through a series of corrugated metal plates. The soldering process ensures a durable and leak- validation unit, and the compact design makes it effective and protean for a variety of applications.